type of jaw crusher is used at vulcan materials

Jaw Crusher - an overview ScienceDirect Topics

Jaw crusher: The material is crushed between a fixed jaw and a mobile jaw. The feed is subjected to repeated pressure as it passes downwards and is progressively reduced in size until it is small enough to pass out of the crushing chamber.

Jaw Crusher SpringerLink

2023年6月21日 Simple Pendulum Jaw Crusher The moving jaw makes a simple swing movement around the suspension point. It is mainly composed of frame, liner, end liner,

Jaw crusher: types, principle and applications ResearchGate

Jaw crusher: types, principle and applications. JAW CRUSHER. A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back

The Ultimate Guide to Jaw Crushing Machines: Types More Tips

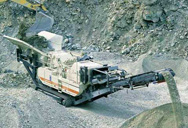

2023年2月21日 A jaw crushing machine is a type of equipment used to break down hard materials, such as rocks, minerals, and ores. It consists of a fixed jaw plate and a

Jaw Crusher Explained - saVRee

Jaw crushers are classified based on the position of the pivoting swing jaw. There are three main jaw crusher types: Blake crusher – the swing jaw is fixed at the lower position. Dodge crusher – the swing jaw is fixed at

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A

2017年6月30日 This study reports on the design optimisation of the swinging jaw crusher plate. Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the ...

Five Types of Crusher in the Mineral Processing - LinkedIn

2020年9月16日 So, the jaw crusher is mainly used for coarse crushing and intermediate crushing of hard blocky materials. 2. Cone Crusher. For this type of crusher, the swing

SANDVIK JAW CRUSHER SERIES - Sandvik Mining and Rock

Our jaw crushers are of the single-toggle type and feature a deep, symmetrical crushing chamber, a large feed opening for its size, and an ideal nip angle that ofers smooth

Jaw Crusher: Range, Working Principle, Application - DSMAC

Jaw crushers are used as primary crushers, or the first step in the process of reducing rock. They crush primarily by using compression. The rock is dropped between two rigid

Our Range of Trio® Cone Crushers Weir

A cone crusher is a type of crusher that is commonly used for processing rocks in mining and aggregate applications. These crushers use compression force to break large rocks (and other materials) into smaller rocks, gravel and sand.. Since its inception, the live-shaft cone crusher design is highly regarded as the benchmark for reliable hard rock cone

Stone Crushers: A Technical Review on Significant Part of

Primary crusher Jaw crusher Expt. + Nume FEM analysis can be used as a powerful tool for analyzing the failure of the component in jaw crusher 2013 Rusi´ nski et al. [16] Poland 3 Primary crusher Jaw crusher Expt. + Nume Regression analysis was done in order to find out the effect of mechanical properties ofrock onthespecific power ...

Selecting the right crusher Pit Quarry

2018年7月25日 The selection of a crusher for tertiary crushing calls for both practical experience and theoretical know-how. This is where producers should be sure to call in an experienced applications specialist to make

Characteristics and Comparison of Four Types of Jaw Crushers

2023年7月10日 For blake-type crusher, its feeding area is fixed while discharging area is changeable. The greatest amount of motion is at the bottom of V which means that it has little tendency to chock. As one of the most commonly used jaw crusher, blake jaw crusher has two types: Single toggle jaw crusher

What Is A Jaw Crusher - MEKA

This is a type of crusher that is widely used in the primary and secondary crushing processes. ... while double-toggle jaw crushers are used mostly for crushing very hard and highly abrasive materials. The lifecycle of double-toggle jaw crushers is longer since they do not apply friction force.

Types of Crushers: What You Need to Know - Machinery Partner

There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers. Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing. The three main stages of crushing are primary, secondary, and tertiary - all of which have their own unique benefits.

Selecting the Right Crusher for Quarry Operations Agg-Net

2014年9月23日 Another critical application factor to note is the effect of contaminated material; jaw crushers do not perform well with materials contaminated with clay, dirt or metal debris. Cone crushers Best suited for secondary crushing applications, cone crushers are designed to crush pre-sized materials, usually 100mm, 150mm, or 200mm,

Stone Crushers: A Technical Review on Significant Part of

2022年5月14日 Based on the mechanism and the type of forces applied crushers are basically classified into three types namely Jaw crusher, Cone crusher and Impact crushers. However, the performance of all the crushers according to specific areas of application is the major point of concern in the research field [ 2 ].

What is the best material for crusher jaw plates?

2020年12月23日 Mn18Cr2 is the most popular material for casting jaw crusher jaw plates. This Mn18Cr2 jaw plates widely in crushing difficult and non-abrasive blasted rock, medium and non-abrasive,non-abrasive gravel, and non-abrasive round rock. Mn22Cr2 Jaw Plates. Mn22Cr2 jaw plates are widely used in crushing hard and abrasive stones.

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER ...

2017年6月30日 Abstract and Figures. A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic ...

Understanding the Different Types of Crushers Agg-Net

2018年9月10日 Cone and gyratory crushers. Cone crushers and gyratory crushers are also compression-type machines that crush material between a moving piece of steel and a stationary piece. The output is controlled by the setting between the two pieces of steel. Though the chamber is round in shape, the moving piece of steel is not meant to rotate.

Our Range of Trio® Jaw Crushers Weir

The materials used to manufacture spare and wear parts play a key role in the performance and ultimate success of your Trio® jaw crusher. Manganese steel has been used in crusher wear parts for decades because of its work-hardening properties. As rocks meet the outer layer of the manganese steel its exterior layer hardens.

Crushers - Akshar International Pvt. Ltd.

We are the leading manufacturers and exporters in India selling and distributing a wide range of Crusher for glass grade material worldwide. Our crushers are widely accepted across various industrial sectors like

Crusher - Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be

Crushing 101 – Different types of crushers for distinctive needs

2020年12月17日 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top

8 Tips for Crusher Safety Stewart-Amos Equipment Company

2022年10月27日 6. Perform Proper Shutdown Process. Ending the operation of a crusher is an essential part of crusher safety. There are a few steps to follow when shutting down a crusher that every trained worker should follow: Shut down the apron feeder. Ensure equipment is free of material. Shut down the primary crusher.

What Are Jaw Crushers and How Do They Work? Oreflow

2019年3月28日 It’s so-called because the opening starts off wide then tapers down to a V where the crushed materials go to. The size of a jaw crusher is measured by the top opening of the crushing chamber. For example, a 48” x 42” jaw crusher measures 48” from one crushing jaw to another and is 42” across the width of the two crushers.

Jaw Crusher: What Is It How Does It Work? - Vykin Machinery

A jaw crusher is a machine that breaks down large rocks into smaller pieces of rock, gravel, or dust. It does this by placing two jaw plates perpendicular to each other and squeezing the rock between them until it is broken into small pieces. A stationary jaw plate and a movable jaw plate control the movement of these jaw plates.

Selecting the right crusher for your operations - Quarry

2020年3月19日 Best suited for secondary crushing applications, cone crushers are designed to crush pre-sized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher. Cone crushers can form finished products down to 12mm or less. Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution,

Different types of crushing equipments - Constro Facilitator

2020年5月6日 Types of crusher depend on the feeding method. These are- Primary crusher, Secondary crusher and Tertiary crusher. The primary crusher is only for the breaking of large stones into pieces (this means primary crusher is not for the aggregate size material.). Examples of primary crushers are jaw crusher; hammer mill crusher and

Message

Related

ecrasement du concasseur mobile de minerai de phosphate

des broyeurs a boulets lubrification

installations de lavage de l or en inde

Usine de broyeur mobile sur chenilles

pierre distributeur de fabricant de concasseur

distributeurs inde charbon machine à laver

prix du jus de canne a sucre chauffe

pierre et de sable concasseur le minerai de fer

usine de traitement de minerai d or au zimbabwe paiement en ligne

concasseur de briques de silice

plantes de depistage du sable en uae

concasseurs de pierres portables dans Himachal Pradesh Inde

Équipement de traitement de sable de Silcia pour la plus grande pureté

machine à laver le sable de minéraux en poudre de feldspath

connaissance de l'extraction du charbon